Laboratory testing

Comprehensive performance testing equipment for building metal envelope structure system

Reference Standard

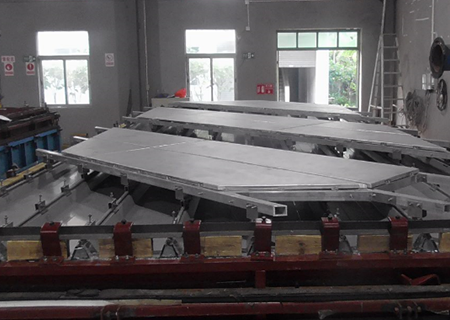

The comprehensive performance test equipment of building metal enclosure system is a full-scale building structure test system, which is used for the performance evaluation of water tightness, air tightness and structural bearing capacity of the building metal roof wall system. The test device consists of a test pressure box, It consists of four parts: fan and pipeline system, sprinkler system and computer control equipment. The upper and lower pressure boxes are respectively simulated by independent wind source generating mechanisms to generate corresponding wind pressure in their respective boxes, and the maximum pressure can reach ±15Kpa. The device satisfies the simulation of static and dynamic wind loads, and can carry out tests of GB, ASTM, AS, BS, CSA, FM and other standard methods.

technical specifications

1. Maximum size of test piece: 7640x3680mm (length x width);

2. Maximum thickness of test piece: 500mm;

3. Test pressure range: 0~±18Kpa;

4. Raise/fall rate: 0.1~3.0Kpa/s ;

5. Fluctuating load frequency: <3Hz;

6. Accuracy of pressure acquisition: 0.05 grade;

7. Sprinkling water volume ≥ 3.4L/㎡·min;

8. Maximum displacement acquisition quantity: 16 groups;

9. Video output format: CSV , AVI, MPEG;

Watertightness Test of Building Metal Envelope System

Reference Standard

ASTM E1646 "Standard Test Method for Waterproof and Penetration Performance of External Metal Roof Panel Systems Using Uniform Static Air Pressure Difference"

JGJ 255 "Technical Regulations for Skylighting Roofs and Metal Roofs"

Test object

Building metal enclosure system, daylighting roof, secondary roof decoration layer, coil roof system

Test parameters

(1) The maximum size of the test piece: 7640x3680 (length x width);

(2) The maximum thickness of the test piece: 500mm;

(3) The test pressure range: 0~±18Kpa;

(4) The rise/fall rate: 0.1~ 3.0Kpa/s;

(5) Dynamic load frequency: <3Hz;

(6) Dynamic load amplitude: 0~±18Kpa adjustable;

(7) Pressure acquisition accuracy: 0.05 grade;

(8) Spray water volume ≥ 3.4L /㎡·min;

(9) Maximum displacement collection quantity: 16 groups;

(10) Video output format: CSV, AVI, MPEG;

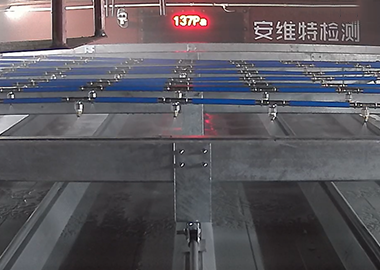

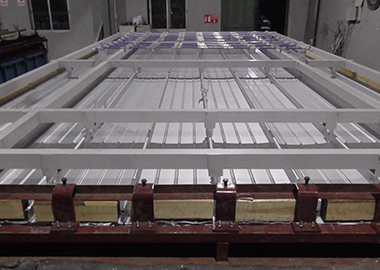

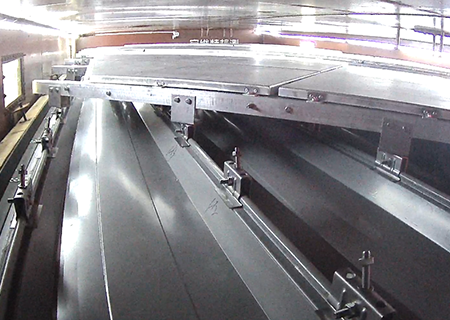

Watertightness test example diagram

Air tightness test of building metal enclosure system

Reference Standard

ASTM E 1680 "Standard Test Method for Air Permeation of Metal Roof Panel Systems"

JGJ 255 "Technical Regulations for Skylighting Roofs and Metal Roofs"

Test object

Building metal enclosure system, daylighting roof, secondary roof decoration layer, coil roof system

Test parameters

(1) The maximum size of the test piece: 7640x3680 (length x width);

(2) The maximum thickness of the test piece: 500mm;

(3) The test pressure range: 0~±18Kpa;

(4) The rise/fall rate: 0.1~ 3.0Kpa/s;

(5) Dynamic load frequency: <3Hz;

(6) Dynamic load amplitude: 0~±18Kpa adjustable;

(7) Pressure acquisition accuracy: 0.05 grade;

(8) Spray water volume ≥ 3.4L /㎡·min;

(9) Maximum displacement collection quantity: 16 groups;

(10) Video output format: CSV, AVI, MPEG;

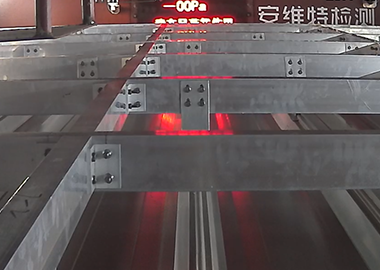

Example diagram of airtight performance test

Steady-state wind load test of building metal envelope system

Reference Standard

ANSI/FM 4474 "Test Standard for Evaluating Roof Assembly Resistance to Simulated Wind Blowing by Static Positive and/or Negative Differential Pressure"

ASTM E 1592 "Testing Method for Structural Performance of Sheet Metal Roofing and Exterior Wall Panel Systems Under Uniform Static Air Pressure Difference"

AS4040.2 "Test Methods for Thin Roof and Wall Cladding Part II: Wind Pressure Resistance in Non-Hurricane Areas"

GB 50896 "Technical Specifications for the Application of Profiled Metal Sheet Engineering"

GB/T 31543 "Wind Resistance of Single-layer Coiled House Systems experiment method"

Test object

Building metal enclosure system, daylighting roof, secondary roof decoration layer, coil roof system

Test parameters

(1) The maximum size of the test piece: 7640x3680 (length x width);

(2) The maximum thickness of the test piece: 500mm;

(3) The test pressure range: 0~±18Kpa;

(4) The rise/fall rate: 0.1~ 3.0Kpa/s;

(5) Dynamic load frequency: <3Hz;

(6) Dynamic load amplitude: 0~±18Kpa adjustable;

(7) Pressure acquisition accuracy: 0.05 grade;

(8) Spray water volume ≥ 3.4L /㎡·min;

(9) Maximum displacement collection quantity: 16 groups;

(10) Video output format: CSV, AVI, MPEG;

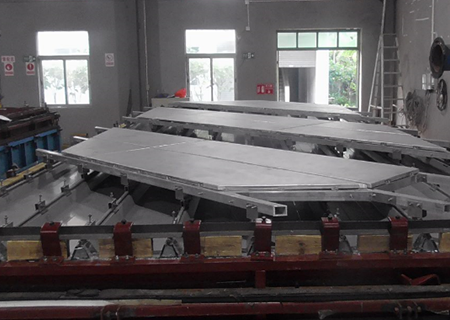

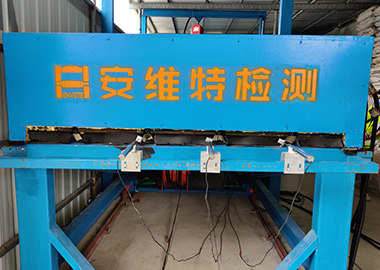

Steady-state wind load test

Dynamic Wind Load Fatigue Test of Building Metal Envelope System

Reference Standard

UL

580

_ Test of wind and tilting resistance of roof accessories"

JGJ 255 "Technical Regulations for Skylighting Roofs and Metal Roofs"

Test object

Building metal enclosure system, daylighting roof, secondary roof decoration layer, coil roof system

Test parameters

(1) The maximum size of the test piece: 7640x3680 (length x width);

(2) The maximum thickness of the test piece: 500mm;

(3) The test pressure range: 0~±18Kpa;

(4) The rise/fall rate: 0.1~ 3.0Kpa/s;

(5) Dynamic load frequency: <3Hz;

(6) Dynamic load amplitude: 0~±18Kpa adjustable;

(7) Pressure acquisition accuracy: 0.05 grade;

(8) Spray water volume ≥ 3.4L /㎡·min;

(9) Maximum displacement collection quantity: 16 groups;

(10) Video output format: CSV, AVI, MPEG;

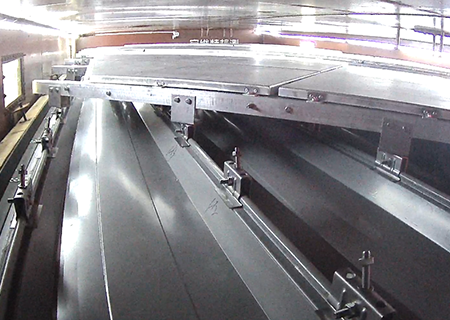

Dynamic test example diagram

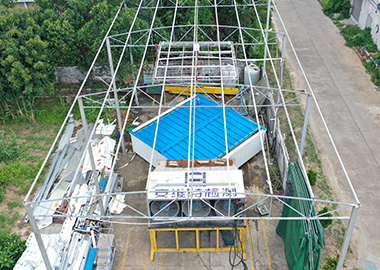

Weather resistance performance test

In recent years, extreme weather has occurred frequently, and the impact of wind-driven rain on buildings has continued to intensify. Water seepage and runoff pollution are prone to occur, accelerating material water erosion and the impact of temperature and humidity environments on the durability of roofing materials. At the same time, the impact of extreme rainfall and simultaneous loads on buildings cannot be ignored. It is very necessary to master the distribution rules and characteristics of building wind speed and rain pressure loads for the design of buildings against wind and rain, and to effectively reduce wind and rain disasters. Therefore, through the wind-driven rain simulation test, the anti-wind and rain performance of the building design is further verified to provide important data support for the design.

Reference Standard

DBJT-15-148-2018 "Technical Regulations for Metal Roofs in Strong Wind-prone Areas" Appendix A.2 Metal Roof Wind Driven Rain Test Method

PD CEN/TR 15601:2012 "Moisture and Heat Performance of Buildings - Small Component Roofs Placed Discontinuously Weather Resistance of Coverings - Test Methods"

AS/NZS 4740: 2000 (R2016) "Natural Ventilators - Classification and Performance"

Test object

Ventilation shutters, metal/non-metal tube tile roofs, engineering enclosures, ventilation caps, buildings with skylights, lighting, ventilation belts and other leaky node structures, BIPV photovoltaic roofs, photovoltaic tile roofs, etc.

The detection device is equipped with

(1) Maximum size of test piece: 6mx6m

(2) Thickness of test piece: 1.2m

(3) Slope adjustment of test piece: 0°~ 90°

(4) Wind direction angle of test piece: 0~360° (horizontal rotation)

(5) Wind source system output wind speed: 0~45m

(6) Artificial simulated rainfall system rainfall: 15~500mm/h;

intellectual property

ZL201921695272.2 Building envelope system wind and rain simulation test device utility model patent

Weather resistance performance test

Temperature field effect test

Test procedure and method

1. One-way specified temperature difference static loading simulation test,

2. Designated temperature difference cyclic loading simulation test,

3. The entrusting party specifies the test procedure method

(Combined with the perennial temperature and climate condition parameters of the application area of the building metal maintenance system, the laboratory simulation test is carried out, the thermal expansion displacement and stress of important nodes and components are collected, and the application safety performance of the metal maintenance system is comprehensively evaluated in combination with the material characteristics of the components required by the design)

Test object

Building metal enclosure system, secondary roof decoration roof system, BIPV roof system

The detection device is equipped with

(1) The maximum size of the test specimen: 10500x2000 (length x width);

(2) The maximum thickness of the test specimen: ≤800mm;

(3) Test temperature range: 0°C~300°C;

(4) Temperature acquisition accuracy: 0.10°C;

(5) Displacement acquisition:

Test range: 0~200mm;

Acquisition accuracy: ±0.01mm;

(6) Static strain collection:

Measuring range: 0~±30000με;

Measurement accuracy error: 0.01%FS±0.5με;

(7) Video output format: CSV, AVI, MPEG;

Temperature field effect test

Heat transfer performance test of building metal envelope system

Reference Standard

GB/T 10294 "Determination of steady-state thermal resistance and related properties of thermal insulation materials with protective hot plate method"

Test parameters

According to the test standard, test and record the heat transfer coefficient and thermal resistance of the specimen (thermal resistance=1/heat transfer coefficient)

test program

Specimen size: 1490mm×1490mm (dimension allowable error ±5mm, at least 1 set is required for testing) The specimen structure should be consistent with the engineering structure, and the structure of the tested specimen can represent the overall characteristics of the engineering. The test system consists of a cold box, a hot box and an external environment box. The test specimens are vertically placed in the middle specimen frame, and the peripheral seals form two closed spaces with the cold and hot boxes respectively. The test method is to measure the energy consumption through the thermal balance of the cold box and the thermal image,

Mechanical performance test of connectors of building metal envelope system

Reference Standard

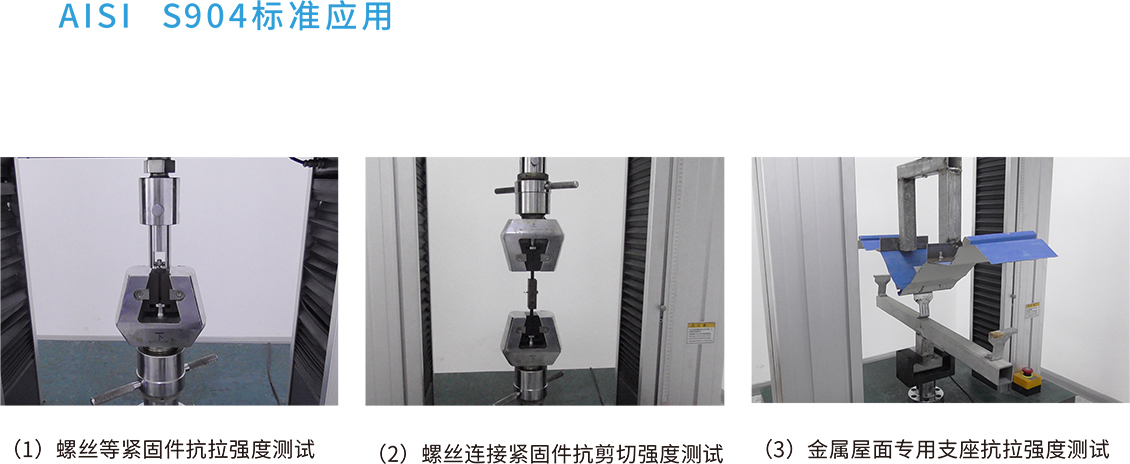

AISI S904 "Standard Test Methods for Determination of Tensile and Shear Strength of Threads"

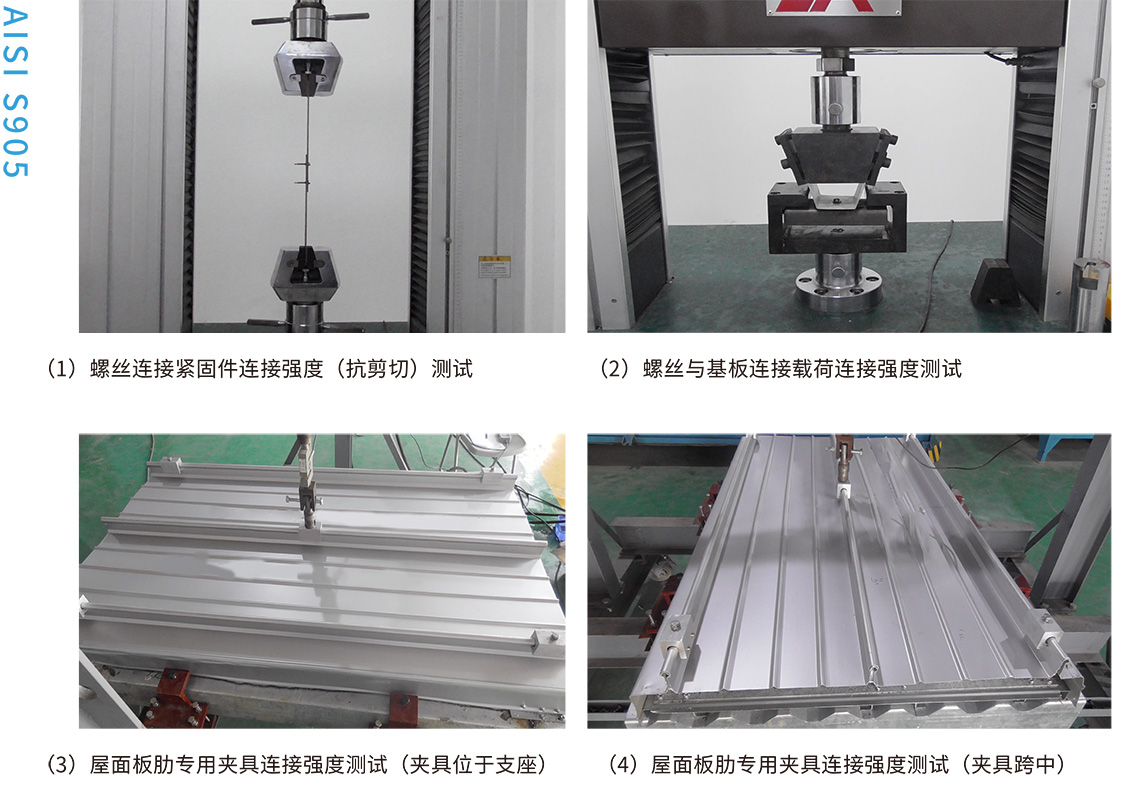

AISI S905 "Test Methods for Mechanically Fixing Cold-Formed Steel Connections"

GB/T 228.1 "Tension Tests for Metallic Materials Part 1: Test Methods at Room Temperature"

Detection procedure

According to the entrusting party's selection of test items and references to relevant test standards, strictly follow the test standards and operating procedures

Test parameters

According to the test standard, carry out the test and record the test results.